Thermal Fluid Solutions, your trusted partner in ensuring the utmost safety and reliability when it comes to thermal fluid systems. We understand that the proper management of thermal fluids is essential for the smooth operation of your industrial processes.

With our expertise and cutting-edge solutions, we are dedicated to helping you maintain the highest safety standards, protect your equipment, and optimise your thermal fluid performance. Discover how we can safeguard your operations and provide you with peace of mind.

By mimicking the conditions required to change the state of the fluids between solid, liquid and gaseous state we can now remove the longer, heavier chemistry typically associated with solids, sludges and discolouration while operates continue to run their plants.

Only with an understanding of the chemistry changes that occur can we successfully remove fractions that simply do not exist at operating temperatures and with the changes in saturation that occurs with temperature change we can

accelerate this process further.

The patented TFS method of VOC removal has been proven to achieve higher flashpoints much faster than any other method available on the market today. A revolutionary, proactive service for the maintenance and safety of thermal fluids, it offers a real alternative to the costly and time consuming process of fluid disposal and re-filling of systems.

The MHTM 2500 Freestanding Portable Thermal Fluid Flashpoint Recovery Unit offers a safe result with minimum input. Different to all other systems that attempt to maintain and recover closed cup flash point degradation due to its unique ability to recover open cup flashpoints and fire points which are both directly related to the risk of fire and explosion in the event of a fluid release.

Spray protection for pipeline flanged joints.

Flanged joints on pipeline systems are a significant source of danger, especially where poisonous, flammable or caustic liquids are being transported. If a seal breaks, the resultant danger zone can be up to 40 metres in diameter. In order to reduce this zone to a minimum and provide the best possible protection for your employees and plant, flanged joints must be provided with a suitable form of spray protection.

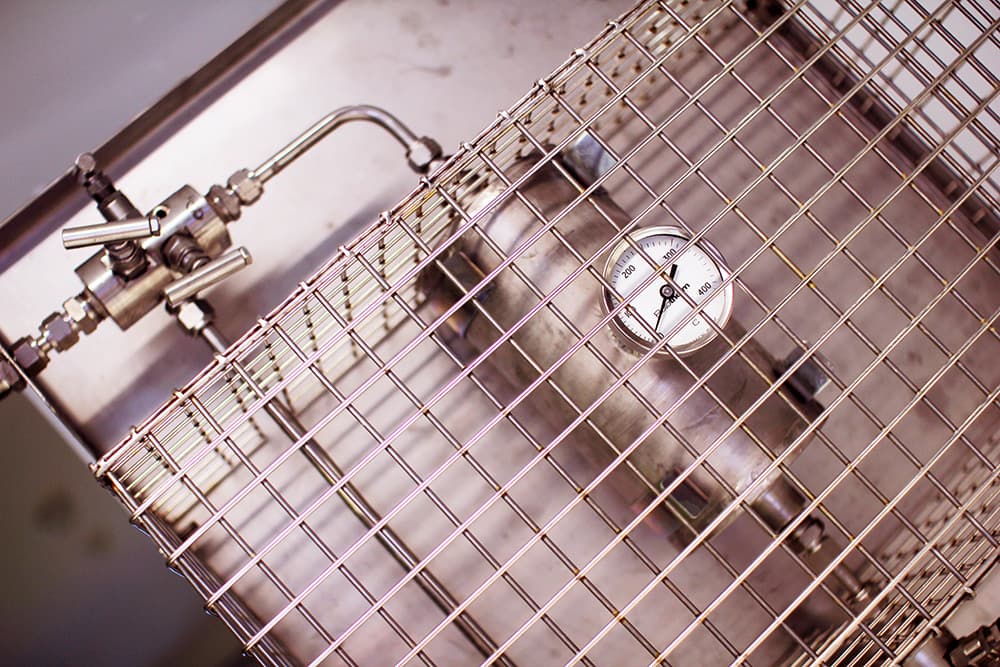

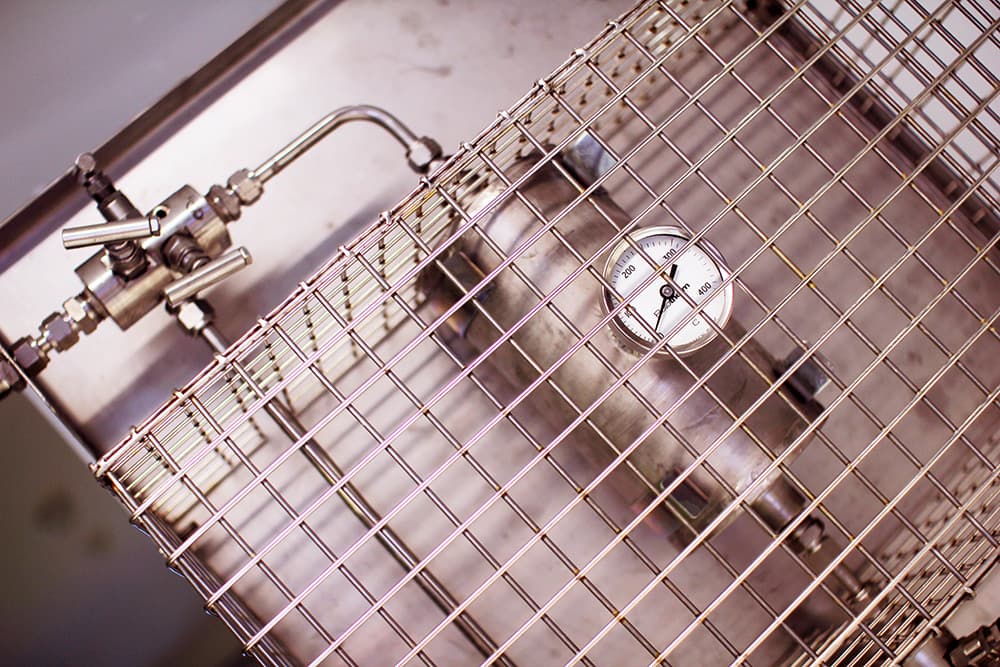

The TFS Sample Station is designed for the safe and convenient removal of a sample of fluid from thermal fluid systems. Fluid is drawn from the system and allowed to cool whilst excluding air.

The assembly is mounted on a free-standing back plate with integral bund and protective mesh so that it can be used free standing or system mounted. The vessel utilises ambient cooling so does not need a cooling water supply, giving more flexible connection options. Standard connection to the unit is 1/2” compression fitting. User specified connections can be provided if required.

The Pump Foam Fire Suppression System is a bespoke site-specific, user friendly and low cost solution offering effective fire control / prevention. The system combines preventative monitoring with active fire suppression response.

Thermal Fluid Solutions highly efficient Foam Fire Suppression System is 100% Fluoro-Free, rated to Class 1-A under EN 1568:2015 for hydrocarbon fires and polar solvents fires.

We can supply a wide range of valves and spares for most types of thermal fluid systems.